Laying cables and lines made easy. With high-quality mesh cable trays at top prices. Find out everything you need to know about purchasing and installing mesh cable trays here. If you live in an apartment building, trellis run safely through your basement. You will also find installations of this type in industrial companies, assembly halls and workshops. Mesh trays are components of cable support systems, but differ from cable trays and cable ladders.

What are mesh trays?

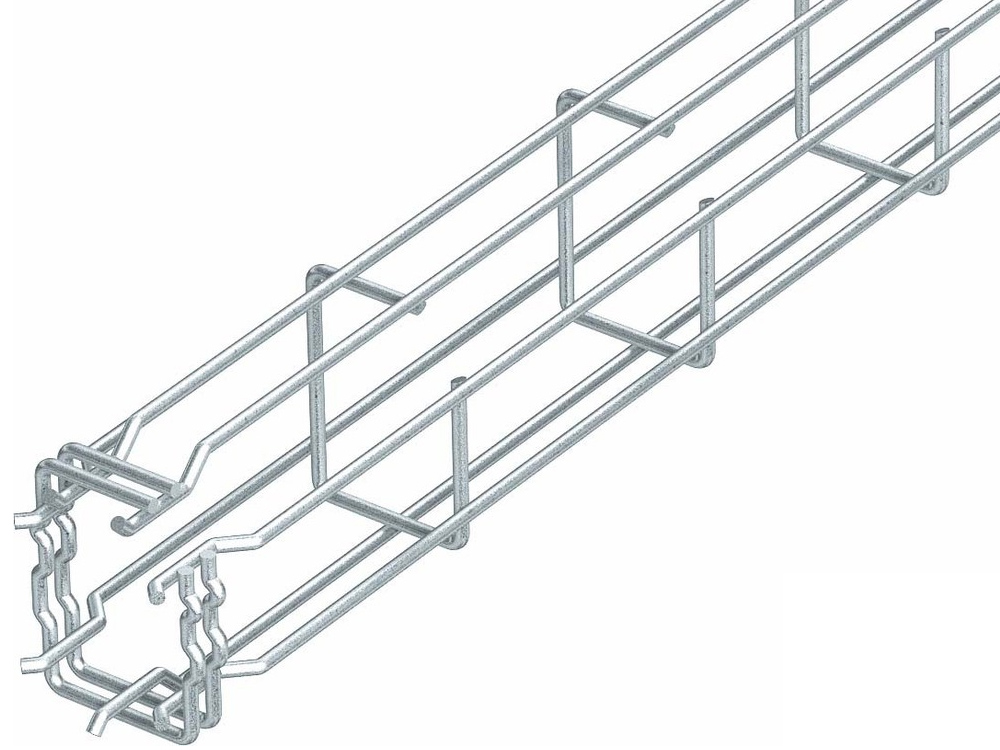

Mesh trays are strong wire meshes based on welded, formed and galvanized metal rods. The result is a grid tray that houses power and signal cables. Mesh cable trays are mainly designed for indoor use. The cables and lines are fastened with clamps or cable ties directly to the metal rods of the channel. The channels themselves usually have a U-shape in cross-section, i.e. a bottom and two sides. For stability, some manufacturers offer extended C-shape and G-shape cross-sections. The G-shape mesh cable trays fulfill the function of open cable ducts.

TIP:

The matching wall brackets and deck supports for attachment to the building are also available here in the shop.

These channels accommodate, guide and support cables and lines. Wire mesh trays can be cut or bent into configurations such as curves, slopes and tees to accommodate complex cable runs. Mounting is typically on walls, overhead, or under floors for whole-building installations. Mesh cable trays are installed as systems. In order to create the required installation route, straight sections are connected to each other using the fittings (bends, angles, reducers, branches) that are also available, as well as accessories.

What advantages do mesh cable trays offer?

Mesh trays are one of the preferred cable mounting systems for installers. This is due to a number of advantages that mesh trays have over closed cable trays or cable ladders. These include:

Material and cost savings

The metal grid is open on all sides and very little metal is needed for it. This saves weight, material and reduces manufacturing costs. Compared to strong wide-span cable trays or cable ladders, resources are saved and the burden on the environment is reduced. As a customer, you will feel this advantage in the price. Mesh cable trays are cheaper than the other systems mentioned.

Solution for all industries

Cable trays are used in a wide range of companies, as well as municipal, industrial and private buildings. The places of use extend to basement rooms, workshops, server rooms, office workplaces and areas with extreme conditions. This can be strong temperature fluctuations, toxic atmospheres or zones with increased pollution.

Customizable on site

Each installation is unique and often requires different twists, bends and pitches to properly route the cable. Mesh cable trays are flexible and can be adapted to the respective situation by hand in just a few simple steps. With simple equipment such as metal cutters, fasteners and a wrench, individual configurations of the cable route are carried out on site without loss of stability. For systems with wide-span cable trays and ladder trays, you must plan and purchase bends, T-pieces and corner pieces beforehand. If your needs change during installation, the parts you purchased may be useless and you will need to order different parts.

Minor disturbances

Due to the low metal content, mesh cable trays significantly reduce the so-called interference in data cables. This is the optimal choice for use in the SCS area.

definition

SCS – Structured Cabling Networks is a user-independent, future-oriented network infrastructure built under economic parameters.

Quick and easy to install

The assembly is self-explanatory. A wide range of brackets, connections and fixings allows installation to be carried out by people with different levels of expertise.

Customizable cable management

Mesh cable trays offer many alternatives for cable routing. The possibility of branching off individual cables and lines anywhere from the cable bundle is particularly practical. With closed support systems, it is not so easy to leave the canal.

Optimum heat dissipation

No heat accumulates in the completely open mesh cable tray. Any heat generated is immediately released to the environment. This provides more security, especially when a large number of cables are bundled.

Safe against pests

Animals can damage cable systems. For example, mesh trays are more difficult for rodents to overcome than closed cable trays. The animals are more likely to fall through the openings and it is more difficult to build nests on the gratings.

Easy control and repair

Mesh cable trays have an open floor plan. It is not difficult to identify problems with lines and cables, as well as to change or uninstall individual lines.

Reduced weight without sacrificing stability

Mesh trays are lighter than other cable support systems, but have the same strength. This makes it easy to ship, store, transport to site, hang and adjust. In addition, there are no sharp edges that can damage the cables and lines.

Image: OBO Bettermann G-GRM 50 50 G mesh cable tray

Image: OBO Bettermann G-GRM 50 50 G mesh cable tray

How are mesh cable trays connected?

Straight connectors or clamp connectors are offered for connecting mesh cable trays. Straight connectors connect mesh cable trays in straight lines and ensure easy cable routing. These are simply pushed onto the ends of the wire mesh trays with a straight cross-section. This creates a secure connection without the need for nuts and bolts. Clamp connectors connect curved or straight mesh cable trays. These are ideal for both simple and complex routes. These connectors require nut and bolt attachment.

What are the dimensions of the trellis?

The classic length of a mesh cable tray is 3,000 millimeters. In individual cases, shorter channels are also available. The height of the sides starts at around 30 millimeters and goes up to a height of around 150 millimeters. You can also choose the width very flexibly. Mesh cable trays are available in widths between 30 millimeters and 900 millimeters. The most commonly used standard sizes of wire mesh cable trays are:

- Width: 50, 100, 150, 200, 300, 400, 500, 600mm

- Height: 35, 50, 60, 80, 100, 105mm

How resilient are mesh cable trays?

When choosing a product, it is worth paying attention to the height of the side, the width of the base and the thickness of the wire. These parameters influence the subsequent load capacity of the mesh cable tray. The number and positioning of the connectors and fastening elements are also decisive for a stable construction. The resilience can therefore not be specified in general terms. The greater the distance between the breakpoints, the less resilient the system is.

TIP:

For the highest possible load capacity, mesh cable trays should always be connected to one another between the spans of the support points and attachment points.

The positioning of the butt joint between two mesh cable trays affects the load-bearing capacity of the system. This should not be done directly where the structure is attached to the building. You will achieve the greatest stability of the cable route when the butt joint is at a ratio of approximately 1/4 to 3/4 to the breakpoints.

Are mesh cable trays high-maintenance?

Electrical installations are typically located outside the normal range of human influence. You often need ladders or scaffolding for checks, repairs or changes. It is therefore important that maintenance work is required as little as possible. Mesh cable trays are very easy to maintain. The metal is protected against corrosion and dirt cannot accumulate due to the construction, which is open at the bottom. The visual inspection of the system can therefore also be carried out from below the mesh cable trays. This saves money, time and cleaning work.

Why should I buy mesh cable trays from eibabo®?

The eibabo® technology store is one of the leading specialist centers for electrical installations. As a customer of our shop you will receive:

- a large selection of wire mesh cable trays of all common sizes

- a simple and convenient ordering process

- many secure payment methods

- fast worldwide delivery with track and trace

- no minimum conditions for the delivery of products

For the mesh cable trays, there are also connectors and brackets for wall mounting and ceiling mounting here in the online shop.

![]()

Catalogue content:

In this eibabo® catalogue Cable carrying systems > Mesh cable tray you will find items from the following product groups:

Item overview:

- Distribution interior fittings

- Grid angle

- Grid track

- Heavy-duty channel

- Heavy-duty mesh cable tray

- Luminaire support grid

- Manifold construction

- Mesh cable tray

- Stainless steel trellis

- Steel mesh cable tray

- Wire mesh tray

from the following manufacturers:

Manufacturer overview catalogue Mesh cable tray:

- Erico

- Legrand Cablofil

- Niedax

- Niedergesäß

- OBO

- Striebel & John